Cooling systems are one of the most important systems in an engine. Running an engine too hot can cause fluids and parts to break down an can ultimately lead to a catastrophic failure. At the same time an engine that is running too cold can be inefficient and poor performing.

There are two ways that engines have traditionally been cooled, by air and by water. Many old cars and even some newer motorcycles feature air cooled engines. However, most modern cars require liquid cooled systems.

A liquid cooled system typically features a radiator, fan, thermostat, water pump, a coolant tank, and a fill point. The type of coolant tank and the fill point location can vary depending on the system. In many modern cars the radiator is mounted lower than the engine. Since the radiator is lower than the engine a pressure relief and fill point that is higher than the engine is needed. This is accomplished with an expansion tank. When the radiator is high enough to act as a fill point and pressure relief an expansion tank is not necessarily required. In those applications a recovery style tank may be used instead.

Liquid cooled systems are pressurized in order to raise the boiling point of the coolant. The boiling point of a 50/50 coolant water mix is 226 degrees F at 0 psi. At 16 psi the boiling point of a 50/50 mix is 267 degrees F. One of the easiest ways to differentiate between an expansion tank and a recovery tank is whether the tank is part of the pressurized part of the coolant system or not.

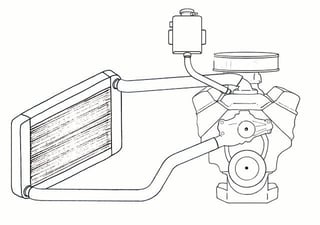

Expansion Tank Set Up: An expansion tank is part of the pressurized section of the coolant system. An expansion tank can easily be recognized by the neck and cap used. Since the tank is under pressure it will require a pressure rated cap and neck, (Shown right). The pressure relief in the expansion tank should be the highest point in your coolant system.

An expansion tank is part of the pressurized section of the coolant system. An expansion tank can easily be recognized by the neck and cap used. Since the tank is under pressure it will require a pressure rated cap and neck, (Shown right). The pressure relief in the expansion tank should be the highest point in your coolant system.

An expansion tank is designed so there is space in the tank for the coolant to expand. If an expansion tank is overfilled it will discharge coolant when the system is at operating temperature.

An expansion tank can also be used as a fill point for the system. When an expansion tank is used the radiator doesn't require a pressure relieving cap. The expansion tanks cap will perform the duties that the cap on the radiator traditionally did. Increasing the capacity of the system and providing a more convenient fill point are among some of the benefits of an expansion tank.

Recovery/Reservoir Tank Set Up:

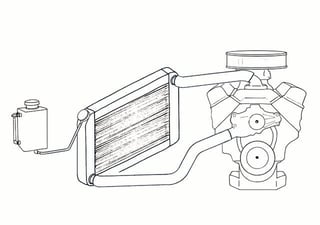

A coolant recovery/reservoir tank gives the system the ability to discharge and recharge coolant when needed to maintain the appropriate pressure. This allows the system to maintaining full coolant capacity at all times.

A recovery/reservoir tank can be used in conjunction with an expansion tank or can be plumbed off of a radiator that features a pressure relief.

A recovery/reservoir tank should not be confused with a catch tank however. A recovery/reservoir tank will either be plumbed at the bottom of the tank or have a hose internally that runs to the bottom so coolant can be drawn back into the system. A catch tank, on the other hand, usually features plumbing into the top of the tank and does not have a hose that goes to the bottom. A catch tank serves to collect expelled coolant to be drained from that tank at a later point. While both a recovery/reservoir tank and a catch tank hold excess coolant, a recovery/reservoir will automatically put the coolant back in the system, where as a catch tank will hold the coolant until it can be emptied.

If you would like to know more about features to consider when choosing a tank open up our Aluminum Tank Designer's Guide by clicking below.

Subscribe to the Canton Blog at the top of the page to receive upcoming posts.