There are a number different direct and indirect causes for oil pressure problems. Everything  from incorrect set up to incorrect installation can create an oil pressure issue. There are even situations that can cause oil pressure drops despite the correct parts selection and flawless execution. In these cases a Dry sump system or even an Oil Accumulator such as the Accusump can prevent catastrophic engine failure.

from incorrect set up to incorrect installation can create an oil pressure issue. There are even situations that can cause oil pressure drops despite the correct parts selection and flawless execution. In these cases a Dry sump system or even an Oil Accumulator such as the Accusump can prevent catastrophic engine failure.

Read about the differences of Wet Sump and Dry Sump Systems HERE. Read about the Accusump Basics HERE.

Parts Selection Mistakes

The first step in the process is usually selecting parts. It is very important to understand what the engine builder is trying to accomplish and how the vehicle is going to be used. The oil pan, pump and pickup need to be selected together in order to operate properly.

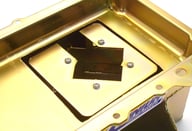

The oil pan should be selected with the vehicle application in mind. In a drag race you will need baffling for hard acceleration and deceleration. A good drag race oil pan will also have features to reduce parasitic power loss. These features also reduce windage which can cause oil pressure issues. You can find more on oil pan selection HERE.

The oil pump should be selected with the engine build in mind. The oil galleys or restrictors typically dictate how much oil can flow to the heads and through the engine. Consider the degree to which your engine's oiling is either open or restricted. Oil pumps vary in pressure and volume. To choose the appropriate pump you will want to match the pressure and volume of the pump to your engine's specific oil flow needs.

The oil pan and pump selection will dictated your pickup choice. NOTE: Some engines feature a pump with a pickup as one piece. Whether the pump and pickup are one or two pieces it is important for the pickup to be between 1/4" to 3/8" off the bottom of the oil pan as well as being situated appropriately in the pan. For instance, in a circle track application the pickup and baffling should be situated so that oil can only get to the back right side of the oil pan. In an Circle Track oil pan we choose this location since a circle track car only turns left, naturally stacking oil into the back passenger side of the pan.

Installation Mistakes

Proper installation of parts is important. Mistakes that can cause issues can happen during the installation of the oil pan, oil system accessories, or in plumbing external oil lines.

One issue that can be particularly frustrating, and messy, is oil leaks. Gone unnoticed a small leak could drain your system of enough oil to cause oil pressure problems. Not to mention the mess that a leak can create in your engine bay and under your car.

Problems with oil pan installation and external plumbing are at the top of the leak cause list. For oil pan installation, be sure to use the gasket recommended for the particular style of pan you are using to properly seal the pan to the block. Gasket recommendations can differ among different pans built for the same engine block. In some installations silicone sealer is a required component for sealing. When using silicone be sure to allow the sealer enough time to set properly before torquing the pan down completely.

Problems with oil pan installation and external plumbing are at the top of the leak cause list. For oil pan installation, be sure to use the gasket recommended for the particular style of pan you are using to properly seal the pan to the block. Gasket recommendations can differ among different pans built for the same engine block. In some installations silicone sealer is a required component for sealing. When using silicone be sure to allow the sealer enough time to set properly before torquing the pan down completely.

NOTE: Unrelated to leaks you should always perform a dry assembly when possible to ensure that all components fit together properly. After assembling be sure to turn the rotating assembly backwards in order to check for clearance issues.

External plumbing leaks can happen at any plumbing connection so checking each connection is important. In addition, pay attention to any oil adapters or sensors that you have installed in your oil system. Pipe thread "NPT" connections which are common in engine plumbing can create a particular challenge. Be sure to use pipe thread sealer on your NPT connections for a leak free fit.

Another installation related issue that can result in oil pressure problems is not plumbing components in their correct flow direction. Many oil system components have a specific flow direction and when plumbed backwards the oiling system will not feed the engine properly. This can cause minor and major engine problems. Be sure to double check the flow direction on any filters, adapters, valves, or other added parts before firing the engine.

Incorrect System Capacity

Getting the capacity of your oiling system correct is essential. Running your oil system under the target capacity can allow the pickup to become uncovered and create oil pressure problems. Learn about oil pan capacity HERE.

In order to prevent under filling your oiling system you will have to consider both your oil pans stated system capacity and the capacity of any external components added to your system. The best thing to do is to start by calibrated your dipstick for the oil pans stated oil capacity. To do this fill the oil pan to the recommended capacity and mark the dipstick. From there you will need to estimate how much additional oil you will need for your external components. Add a little bit less then that into the engine. Remember, it is easier to add a little more oil later then it is to remove it.

In order to prevent under filling your oiling system you will have to consider both your oil pans stated system capacity and the capacity of any external components added to your system. The best thing to do is to start by calibrated your dipstick for the oil pans stated oil capacity. To do this fill the oil pan to the recommended capacity and mark the dipstick. From there you will need to estimate how much additional oil you will need for your external components. Add a little bit less then that into the engine. Remember, it is easier to add a little more oil later then it is to remove it.

Now, let the engine run for a few minutes to fill all the additional components. Don't worry about being a little under filled at this point. Since you are running at low RPMs and stationary this will not be a problem. Lastly, turn the engine off, let the oil in the engine settle, then refill your engine up to the level that you set for the pan initially.

Insufficient Baffling

Another cause of oil pressure drops in race cars is insufficient oil pan baffling. Most stock oil pans are built with a very basic purpose of holding oil but not necessarily controlling it. OEM oil pans are designed with standard road driving in mind not necessarily high g-force situations from hard acceleration, deceleration and cornering.

In track conditions a stock oil pan will not be able to prevent oil from moving away from the oil pickup. In these situations where there is no oil under the pickup the engine oil pressure will drop. At high RPMs this can be particularly damaging and can create significant problems for engine operation. To learn about what is happening in your oil pan click HERE.

Oil pressure problems can ruin seasons and racing budgets in a matter of seconds. Unfortunately, oil system components are one of the more commonly overlooked parts of a performance vehicle. Often issues are only addressed after catastrophic failure. Preventing these failures can be simple and done before they cost you time and money.

Want more info on what you can do to prevent oil pressure problems? Check out our "Oil Pan Feature Guide" below for a visual overview of what to look for in an oil pan.